Factory Customized lathe accessories from Xiamen China

Advantages of Nickel

Nickel has certain strength and good ductility. The addition of nickel to stainless steel enhances the steel’s corrosion resistance and enables strong, malleable and strong welds, ensuring stainless steel can be used in strong and durable structures. Similar structures include the new San Giorgio Bridge in Italy designed by Renzo Piano. The new bridge was built after the catastrophic collapse of the old bridge. Reinforcement is a key link in ensuring bridge durability. The mechanical strength and corrosion resistance of the new bridge is ensured by the use of stainless steel reinforcement. Factory Customized lathe accessories from Xiamen China

new st george bridge

In August 2018, the Morandi Bridge in Genoa collapsed. A subsequent independent report pointed to poor maintenance and flawed bridge design and construction as possible causes of the fatal accident. Cable corrosion at the top of the stay cables on the south side of one of the pylons is believed to be the main cause. In addition, the lack of regular inspections is said to have resulted in a lack of adequate knowledge of the actual state of degradation of the cables by service personnel.

Since the Morandi Bridge accident, there has been a growing awareness of the robustness and durability of bridge design. The new San Giorgio Bridge in Genoa (the new bridge, see Figure 1) was designed by Renzo Piano and will be inaugurated in 2020. Different from the cable-stayed design of the original bridge, the new bridge uses stainless steel reinforcement, which not only ensures mechanical strength, but also ensures corrosion resistance. Factory Customized lathe accessories from Xiamen China

picture

In the design stage, the most critical areas are all made of stainless steel. For example, in the pedestrian bridge area, stainless steel rebar was selected and placed next to the rebar near the core of the deck. Carbon steel and stainless steel are in contact with each other, and there is no increased risk of carbon steel corrosion when concreted.

Reinforce where needed

Stainless steel prevents corrosion, cracking or spalling of structural components that are regularly exposed to atmospheric media. In fact, in very harsh environmental conditions, such as marine and port structures, it is necessary to use materials with the right properties. Without the use of stainless steel, external factors can cause carbon steel rebar to corrode, causing it to increase in volume, and concrete to crack over time, further deteriorating the structure.

304L (UNS S30403)/1.4307 stainless steel bars of different diameters were placed on the outer surface of the concrete structure in parts of the structure where the concrete cover was thinner and more susceptible to corrosion. Carbon steel rebar also ensures the structural integrity of the concrete if there are no exposure issues (such as in most concrete). Factory Customized lathe accessories from Xiamen China

long-term value

The St. George Bridge uses 9,000 tons of carbon steel rebars and 250 tons of stainless steel rebars, with a usage ratio of only 3%. For reinforced concrete projects exposed to corrosive conditions, it is typical to use a usage ratio of 1%-5%. In practice, following the ratio principle can also help reduce the overall cost of infrastructure projects.

When addressing the challenges of harsh marine environments, stainless steel can provide significant savings in overall bridge maintenance costs, proving to be the most economical solution in the long run. Stainless steel also offers other important advantages in marine environments, such as excellent mechanical strength, high ductility and excellent energy absorption during earthquakes.

critical connection point

Advantages of strong bolts

Bolt failure due to overloading, fatigue or corrosion can be very costly, especially when a bolt must stop critical operations during repairs. Factory Customized lathe accessories from Xiamen China

Fasteners can be made from a variety of alloy steels. Therefore, to avoid failure, it is important to ensure that the correct steel is selected and to have some knowledge of the application details. In addition to the loads to be carried, issues to consider include the accessibility of the connection, the environment (temperature, water exposure, corrosiveness) and the materials being connected. Reusability and installation procedures are also important considerations. To ensure failure-free life and keep life-cycle costs low, the selection of the right steel grade and properties must be considered.

Critical in demanding applications

Stainless steel fasteners are widely used in demanding industrial fields such as water treatment, wind energy, chemical, marine and subsea equipment, where carbon steel fasteners cannot meet the requirements. Stainless steel fasteners are available in a variety of grades and service conditions, with varying strengths, corrosion resistance, and ability to operate at high and low temperatures. When connecting stainless steel components, stainless steel bolts must be used, in addition, stainless steel bolts can also connect galvanized steel and aluminum components. For example, the structural members of aluminum helidecks on offshore platforms can also be connected by stainless steel bolts. Factory Customized lathe accessories from Xiamen China

long-term cost advantage

Although stainless steel is more expensive than carbon steel, the savings from its long-life, low-maintenance properties can easily outweigh the initial cost in demanding applications. For example, in 2019, around 6,000 duplex and super duplex stainless steel fasteners were used in the construction of stainless steel bridges and the lining of old Victorian sewer lines in London, UK. A low maintenance solution with a 120-year design life was extremely important due to the project’s impassable bridges or pipeline outages, as well as difficult maintenance. Furthermore, the structure needs to be compact and able to carry high loads. High-strength duplex stainless steel bolts with a nickel content of 5% to 7% have become an inevitable choice. Utilizing the high strength of duplex stainless steel, the size of the connector can be reduced, saving material and cost, and there are also health and safety benefits due to less material handling. Figure 2 shows the use of stainless steel supports to connect the canopy at Porto Airport in Portugal.

Seeking new alloys with practical value

History has proven that the development of new metal alloys is a costly, inefficient and time-consuming trial-and-error process. It is usually based on metallurgical knowledge to formulate new alloy compositions and determine forming and heat treatment processes in an attempt to enhance the properties of materials based on existing alloys. A series of experiments are required to melt and test the material to tune its properties.

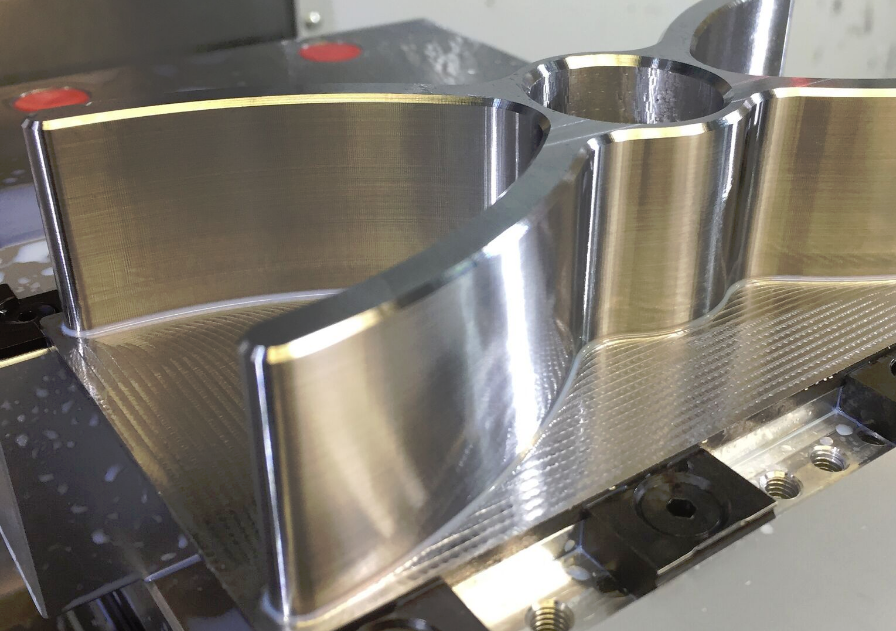

About two decades ago, the advent of Integrated Computational Materials Engineering (ICME) research and development marked a shift from physical experiments to virtual simulations. Questek Innovations has developed several performance-enhancing nickel-containing alloys using this approach. For Ferrium’s range of products, Questek has developed a nickel-containing, high-strength, corrosion-resistant steel, Ferrium S53. It was the first ICME-designed material to qualify for the Aerospace Materials Specification (AMS) and Metallic Materials Property Development and Standardization (MMPDS) and as the material for the safety-critical landing gear on the U.S. Air Force T-38 training aircraft. Ferrium S53 is an ultra-high strength steel that can be used in aerospace structures and other applications where AISI 4340 is commonly used. The mechanical properties of Ferrium S53 are comparable to those of these alloys, but with the added advantage of atmospheric corrosion resistance without the need for a cadmium coating. Another product developed by the company is the nickel-containing steel Ferrium C64, which is an alternative to high-performance gear steels such as AISI 9310 (see Figure 3). This material has ultra-high strength and high fracture toughness, as well as excellent fatigue and heat resistance. It can be used in critical aerospace and automotive manufacturing, such as rotorcraft and racing gears, and in the energy sector.Factory Customized lathe accessories from Xiamen China.