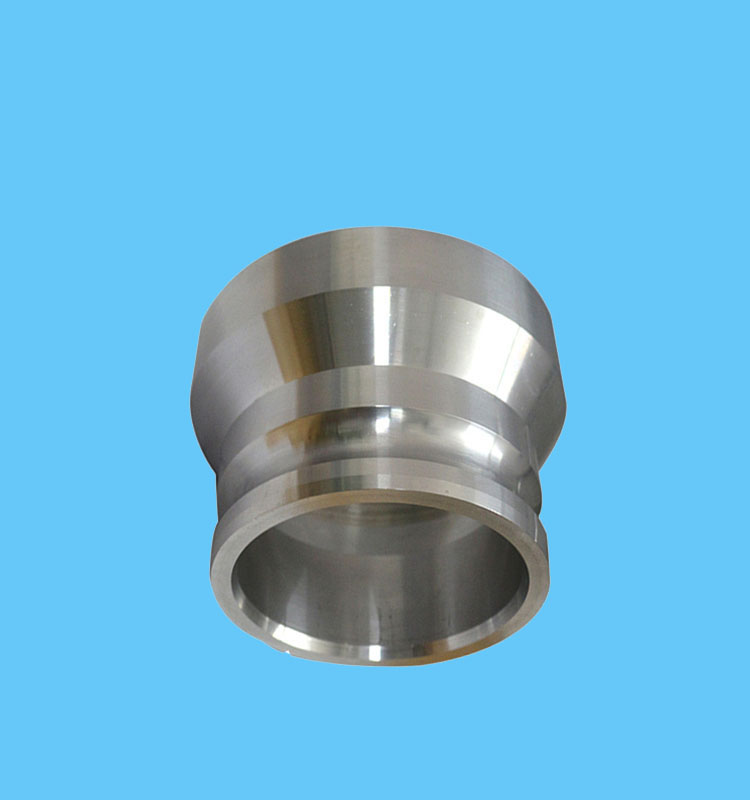

Precision cnc customized brass sleeve

There are a lot of new things in the industrial robot industry recently, and I haven’t finished summarizing them a few days ago. Today, I will continue to take stock of new developments, new technologies and robot application cases in the field of industrial robots for readers’ reference. Precision cnc customized brass sleeve

- Yuejiang Technology and BYD have reached an in-depth cooperation

On March 31, Yuejiang Technology and BYD reached an in-depth cooperation. The two parties will carry out comprehensive and in-depth exchanges and cooperation in intelligent manufacturing equipment products, robot production and deployment applications, and jointly promote the transformation and upgrading of intelligent manufacturing. Yuejiang Technology CEO Liu Peichao and BYD Ninth Division General Manager Liu Xiaoliang and other representatives attended the signing ceremony. Precision cnc customized brass sleeve

According to the agreement, the two parties will give full play to their respective advantages and strengths in technology, products and markets, and carry out comprehensive cooperation in all fields of robot intelligent manufacturing applications, including but not limited to robot technology development, robot production, robot application development, and intelligent manufacturing talent training. , jointly explore the innovative application of robot technology in the field of intelligent manufacturing, jointly promote the research and development and industrialization of intelligent manufacturing products, and provide global customers with smarter products and better services.

- The B+ round of Han’s Robot increased its capital by nearly 200 million yuan

At the end of 2021, Han’s Robot completed the B+ round of capital increase, with a total financing of nearly 200 million yuan. This round of capital increase was participated by Yuecai Fund, Qilu Investment and Wuxi New Investment. This is the second time that Han’s Robot has won the favor of investors after it received 165 million yuan in Series A financing and 395 million yuan in Series B financing in September 2020 and June 2021. Precision cnc customized brass sleeve

While consolidating its leading position in the field of collaborative robots, Han’s Robot accelerates the landing of high-quality products in more scenarios and regions, and fulfills its corporate mission of serving the people with robotics technology.

- The Stäubli robot launched the end effector, 2500kg high load quick change

Faced with the growing demand for high-load quick-change applications in the aerospace, automotive (heavy truck) and other industries, Stäubli has further expanded its product range of robotic tool quick-change systems, adding “heavyweight” new members —MPS 2531. The newly launched MPS 2531 breaks through the original 1500kg maximum load of Stäubli MPS series products and increases to 2500kg.

The maximum static bending moment and torque of MPS 2531 are as high as 33,000Nm and 44,000Nm, respectively, and the corresponding maximum dynamic bending moment and torque are 66,000Nm and 110,000Nm, which can achieve higher elastic cooperation with the robot, while ensuring that the performance data is at a high safety factor. Precision cnc customized brass sleeve

The combined height is only 110mm, and the self-weight without modules is 50.6kg. It is more compact in the large-tonnage quick-change system with the same load range, and can better meet the heavy-load work requirements in a narrow space.

With a repeatable accuracy of ±0.01 mm, the tool can be brought to its precise working position even with a large number of switchings, achieving the highest production efficiency required for high-frequency switching, while ensuring safe and error-free operation.

- Comau launched a new generation robot N-220-2.7

Comau’s new N-220-2.7 is a 220kg payload robot with modular setup, positive kinematics, absolute calibration and enhanced algorithms. These features make it easier to use, more straightforward to integrate, and faster to maintain after assembly, while ensuring accuracy, flexibility, repeatable positioning and minimal backlash. Precision cnc customized brass sleeve

Manufactured at Comau headquarters in Gloriasco (Turin), Italy, the robot uses a state-of-the-art robotic assembly line to reliably automate assembly, spot welding, packaging, material handling, and continuous machining operations such as 3D printing with glue.

Comau’s e-Motion software algorithms reduce cycle times and improve motion quality and path control. Thanks to the use of a nitrogen balance system on axis 2 and a larger travel range on axis 3, the N-220 has increased flexibility and a wider rearward working area, making it ideal for bending and handling operations. Because the N-220 uses only two motor sizes and one oil type, replacing a failed motor is quick and easy. Another advantage of the simple, modular construction is easier overall maintenance, with improved mean time between failures (MTBF) due to 50% fewer robot components. Precision cnc customized brass sleeve