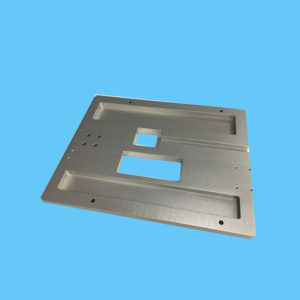

China turning aluminum Manufacturer

First

This even, more, less;

Most of the inspectors do not love open bad report, of course, suppliers love, because of a bad report, take the bad product to find the boss to sign, the boss will notice signed purchase; supplier factory to confirm rework in heavy industry, heavy industry after also re sampling. According to the standard and so on, reject a group of more than the normal inspection batch. Therefore, most of the time, the inspector in pumped to the poor quality and less, but the bad number has reached AQL rejection standard, still stick labels on the line. This is wrong, before I take the inspectors, basically, each new the inspector should be eating such a deficit: several bad products can only be found in the inspection time, results in the production process, quantities of bad products broke out due to a production line stop phenomenon. Therefore, when the sampling reached LTPD AQL, We must reject the single. China turning aluminum Manufacturer

Some inspectors found poor billing fear trouble, after purchasing said, this problem I call the vendor over heavy enough, don’t trouble for billing, billing, when this kind of phenomenon when the inspectors are often willing to help, and procurement will pressure down, the supplier is not timely, resulting in the production line no material stopping line are some material feeding for three days, also did not sign the bill and so on. Superiors do not know the circumstances, as the inspector did not test would say that the limitation of the inspector. Therefore, the inspector in inspection to bad, should be timely billing. China turning aluminum Manufacturer

Two

Procurement, business, technology, production that can be placed, so I put

You know, the inspector is inspection according to inspection standards, inspection standard drawings, specification, standard, test samples and so on; if found inconsistent with the standard, you should give your supervisor confirmation. Instead of the other departments that can. Inspector management, performance appraisal in quality department and since you listen to other departments, the direct transfer to other departments, you pay by other departments issued it. China turning aluminum Manufacturer

Once encountered such a case, the inspector check to the unqualified material procurement, said, this does not affect the production line, I give a good call, they are willing to produce; not complain to you, the inspector has not reported to their superiors, directly paste the qualified logo, on-line production. Lead production line complaints, stop line; it won’t take the responsibility. When the material is caused by production problems, other departments will only ask the inspector is how to check, do not blame people in other departments. The unqualified results bear only the inspectors.

So, if the inspectors found adverse results directly, can only listen to the boss and the boss to accept, also need to specify the reasons in bad report. Commuted. China turning aluminum Manufacturer

Three

Meseems

When the inspectors do not check the duties, ask the reasons of losing control in the beginning, always say “I think..” inspection personnel should not say “I think” when you say “I think” when you start looking for reasons for their own fault, find an excuse to find an excuse. Also after repeated. Furthermore, if the problem can not be confirmed, first to confirm; therefore, the consultation, I asked my staff to make mistakes, not to say “I think” how are you going to do I want to know is the cause and the next inspection were not detected, only good can close.

For example: this test is not my sampling method, to 6000, there are 5 pallets, 200 boxes, 32 boxes should be in accordance with the requirements of testing, each pallet average sampling 6 boxes; each box pumping 6; and I only test a pallet, inspected three boxes. Not bad products focused on the pallet, I’m not pumped to the cause. Follow me according to standard test method of sampling to sampling. China turning aluminum Manufacturer

Four

By experience, the relationship between the material will not be a problem, exemption

This is the old inspector often make trouble, fortunately, the inspector to work to end, know the focus testing, but the wrong way. Have no problem, but less inspection, but can not be free, at least should check the box logo, to make comprehensive inspection to get a product. Usually, for no problem the product, the first box and the mantissa box must check. So, at least to ensure that the material does not appear the bulk of the problem.

The manufacturer (monitor) and I have a good relationship, I also bought a drink yesterday, gave me cigarettes; the bad even, this is the PASS. inspector general, taboo, will happen. As for friends face, the results of their own return sank in. When you put this batch of bad customers inspection, making production line problems, then, first ask the leader is how do you test this problem, why not see? Because of a face problems, causes the loss of the company. It is not desirable. China turning aluminum Manufacturer

Five

The last time billing are changed, concessions, this is not open, directly attached to PASS

Sometimes, due to material to line, there will be a lot of revision, this phenomenon can lead to errors of the inspectors received. Second inspection found the same problem, not on the line after the billing, resulting in the production of complaints.

The boss will be commuted this batch will be the boss considered, depending on the actual situation, some communication with customers, and some production of communication, selection and so on, are limited. So in this batch, found unqualified, although the number is changed, but should be the same billing, rejected.

Six

Missed items

Because the material is urgent material, procurement, production department are in the rush, so some of the test items and items without inspection, think there should be no problem; the PASS label on the line. Each company, due to the procurement of aging and other reasons, basically have urgent material, material procurement to have on-line follow inspector check the speed of material, production, warehouse personnel material inspection, the inspector inspector in beside immediately. This issue from job to inexperienced inspectors caused great psychological pressure. Because flustered, some inspection items did not check, directly pass label on the production line. Because the results did not check into the project there is a bad phenomenon, make the production line stop punished. China turning aluminum Manufacturer

Some are usually purchasing a call supplier urgent material purchasing production quickly, as long as the goods come up within the specified time, the quality of the other problems are whether the supplier to normal delivery, to catch the goods produced, the material quality will be good to go? Is it more urgent material the more carefully check. Usually urgent material is more prone to quality problems. When purchasing or other relevant units and personnel inspection inspectors to urge them to go to the specified area, etc., the analyst should in accordance with the requirements of all inspection procedures inspection confirmed that no end. It can be put to a bad line. If found during inspection bad should notify the relevant personnel to deal with.

Seven

No more process checks are found after the problem is found

A bad phenomenon of A, found in the inspection process billing, processed (heavy, special mining etc.) on the production line and found adverse B inspector according to the inspection procedures for inspection, inspection of general order packaging, appearance, body size, performance check. There are a lot of time, when the inspectors found a bad, the inspector is very happy, stop the test, immediately issued unqualified report. The quality management in previous work, eat a lot of losses, when the inspectors to look bad (scratch); due to the production, purchase concessions on the production line in the process, found another problem: the size of the problem, unable to assemble.

Therefore, the inspector in the inspection process, if found, should also put all the defective items all inspection, record the inspection results, to be tested after the completion of billing. China turning aluminum Manufacturer

Eight

After rework, the product will not be checked again

During the inspection, found the bad; by the supplier or production after rework, should not have what problem, less check or direct PASS. have a lot of time, the supplier sent heavy personnel work is not serious, want to go back, or after heavy play out, there are a lot of material results, see, some boxes are not open in the middle. The inspector to test, that all suppliers to complete heavy, symbolically sampling, posted on PASS, the supplier let people go, the result was still on the line after the production of complaints, the incoming material.

Therefore, according to the supplier after rework products, the inspector should also be in accordance with the inspection requirements for re inspection of the material, when the test to the bad after the supplier is required to re repair, until the inspection so far. The heavy personnel must not believe.

The above problems, we should be how to improve these problems, then we how to be a good manager, how to do? That is our usual managers should focus on staff education, focus on the cultivation of employees and habits.

China turning aluminum Manufacturer

CNC Machining Service & CNC Machining parts