How did you get into the field of quality? Unsurprisingly, all of us who entered the quality department were originally ‘scared’. I, including my friends around me, were forced to assign the quality/quality department to the first work group. At the beginning, I didn’t know anything about it, but later I learned it. It’s a formal approach. After I lost my mind, I thought about escaping from this field, such as “purchasing” or “R&D” or “business”, because I’ve been able to hear it there. In return, the salary/revenue is considerable; but only a few leave the real departure, so there will be a lot of latecomers in the quality field, the younger generation. rapid CNC

How do you start at the beginning? Generally, in the formal company, after entering the quality/quality department, you will respond to the internal training, so that you can understand the theoretical knowledge of the system. After the “boring” theory class, you will feel it. There are not many things, although most of the time it is not a problem to understand. The next step is normal work. If the company’s atmosphere is good, there will be experienced QE to help you, take you; if your company is generally or not good, then you will see your creation, and how much really useful thing is up to you. Sharpness / self-positioning, because there is no pressure for “exam” and “high school entrance examination” at this time, how do you learn, learn and not learn, how to do it in the short term is not clearly different, plus every month everyone “is It’s not so different to receive so much salary, but the gap is often generated when it doesn’t matter, and graduated together, a person who is clearly motivated and optimistic, and a person who doesn’t get into the day’s day, work 1-2 There may be no difference in the year, but the distance between two people will be opened in a few years, and that you will make up for it after that distance. Because people accept things with a ‘pre-emptive’ concept, learning what depends on your own attitude and positioning, as a famous saying, theoretical learning is a superfluous thing, its effectiveness depends first on you. Only a tiger, not a cat. rapid CNC

Do you think that quality management is a sloppy work in the field of unrewarding 1-2 years? Did you find that the quality of this department is not working well, and often feel that it is hard to please? Young and sturdy, you have definitely touched a lot of nails in the past 2 years. You have suffered a lot of white eyes and have been complained a lot. This time is your intersection, and the students who graduated in the horizontal comparison, the people live more moist… The lack of determination is beginning to shake the original choice is correct. Next, I began to envy the rest of the company and fled the quality/quality department. Some people began to escape the quality field by replacing departments/companies. It is not too appropriate to escape, and there will be many successful developments in other areas after giving up this field. .

If you persist, you are a helpless or self-reliant choice. There are two kinds of people who insist on it. One is helplessly staying; the other is the active and firm stay. Which one do you belong to? rapid CNC

I think that my colleagues at work are divided into two kinds of people. One is to do things, and the other is not to do things.

The typical feature of doing things is that no matter what company he can quickly enter the role, insight into the company’s hidden problems. Usually, he is not very busy. As a result, the key problems of others are handled very well. They absolutely insist on their opinions on serious issues and do not give up/compromise easily. The general anecdote with him is the impression of the accuracy of the work/analysis. Here is the emphasis on colleagues who have shared things, not all colleagues. He also has a great advantage that his insight/minance is extremely strong. The typical feature of not doing things is: it seems very busy, but after doing the tired and tired, everyone does not recognize his results, and even complains about him; there is no opinion on the key issues, the wall grass is falling. Most of the time, I’m talking about it, but I’m really having a tough problem, and my face is red and I can’t tell a plan! rapid CNC

How do you know how to manage quality management? If you can’t do it, what is the reason for your job? After a few years of work, change a few jobs, and count as an insider. You have your own opinion on the word QUALITY. Quality management is very different in different cultural contexts under different conditions, but the core is the same. You want the boss to think that you are the right person. What you do is to reduce the cost and loss of the company. The ‘hospital’ that makes the boss happy when they encounter a major problem!

Don’t talk about big theory, reason, complain every day that this boss does not support, the boss does not pay attention, first look at his own work in place. Again, the best place to test a good worker is when I think it’s the time to deal with the problem, especially the big one (of course, if you usually do this big problem, maybe it won’t happen once in 10 years), what you did when it happened. The final result makes others have nothing to say. The highest evaluation is that the boss wants to invite you to dinner! rapid CNC

How many years have you served a few companies, why have you stayed, and why you have learned how many work experience and how many companies you have served when so many company recruiters. Very simple, to some extent, to buy your experience, let your experience quickly make up for his shortcomings and reduce losses. Quality management is as big as the company’s overall strategy, and it is small enough to face the handling of a simple incident/attitude.

Most companies lack specific actions to break down/implement the so-called quality strategy to all levels! The boss feels enough attention, but it has no effect, huh, huh. The above is anxious, the following is also anxious, every day when looking at the REVIEW indicator, watching the high-firing numbers frequently shake their heads! There is also a company, the internal indicator data is so good, I feel that everything is good, but every once in a while, a ‘significant complaint’, the boss’s wallet is slamming! rapid CNC

Did you suddenly find that the so-called quality work encountered a “bottleneck” to a certain level, feeling that your work no matter how you do it, or how to change your work/environment at a level, how can you not go up, everyone has everyone The view, some complain about the environment, some ….., have encountered, how is your bottleneck caused? Many people feel that their career has come to an end when they encounter this bottleneck.

Does the company’s quality system avoid the company’s greater losses, or how many companies have achieved significant customer complaints/quality problems due to quality objectives, resulting in company recall/replacement/maintenance costs, and your goals can be trusted? Long-term treatment Whether a company’s quality objectives are met, and why is there such a stupid question under the excellent “performance”? rapid CNC

A company that has been in the world, hundreds of the world, self-proclaimed to be the world’s number one in some areas, and in the days I stayed, I was deeply impressed with the first feeling. I will not believe that such problems will arise without killing me before. For example, the company’s net profit this year is 1000WUSD. At the end of the year, the bosses receive dividends. As a result, a phone call is made when the red envelope is removed. The company’s tens of thousands of UNITS products need to be recalled for repair/replacement! The initial estimated direct loss is 2000WUSD! Not to mention indirect, market impact, corporate image / brand loss. Although this is an ‘accidental incident’, this accidental discovery found the inevitable sign! At that time, I felt that what did our quality system bring to us? rapid CNC

The future direction of quality management / where is the way out, I have been working for more than 3 years, I think there should be a large number of people who are aware of the bottleneck in this field of work, what is the root cause. According to this, some people choose to continue numbness, some people choose a firm struggle, and some people bravely challenge / clear this root cause. In addition to the fake quality people, the authentic quality people, plan their own job map for their own characteristics / ability, at the end of the MAP you will find it ridiculous, then you are not a quality person this group!

After so much, I can finally return to the theme. After the above experience, I found that the root of the problem-solving problem is the disguised disengagement of the mass person group. In this way, it seems that it suddenly returned to the first intersection of the starting point, the only one. The difference is that this detachment is sublimation, and the last time is escaping. rapid CNC

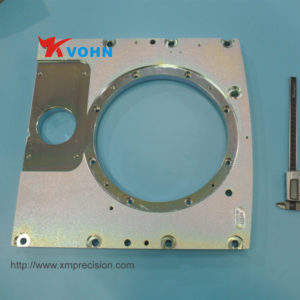

CNC Machining Service & CNC Machining parts

dci dental equipment

precision machine inc

precision machined parts

steel fabrication shop