Sourcing metal supply company Manufacturer from China

01 Background

What I want to talk about today is an application case in the automotive industry. It is an auto parts supplier from North China. Its automotive supporting fields cover tires, body and chassis, powertrain systems, electronic systems, exterior trim systems, and seat systems. , locking system, mirror system, roof system, etc. The products are also exported to the United States, Mexico, the United Kingdom, Spain, Japan and India and other countries and regions, and provide BMW, Mercedes-Benz, Geely, BYD, Dongfeng and other well-known domestic and foreign auto companies. Systematic total solution. Sourcing metal supply company Manufacturer from China

02 Pain points

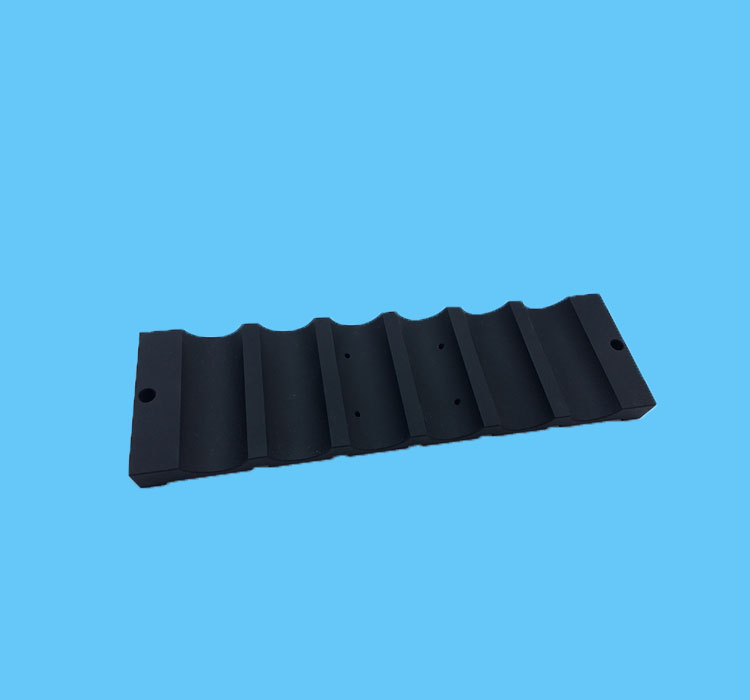

This case is based on the car seat inspection project. The company has an annual production capacity of 5 million sets of seats, and the car seats are complicated in style and specifications. Its product series and varieties can reach more than 300 varieties. Before the introduction of collaborative robots, seat detection was basically done manually. With the increase in production capacity and labor costs, we have been looking for suitable non-standard automation solutions to realize robot substitution.

As a special-shaped irregular part, the car seat requires the robot to follow a relatively complex trajectory during the detection process, and is equipped with a vision system to complete the photo detection of multiple positions and angles. Moreover, with the increase of small batch and multi-variety orders from end customers, the company requires robots to be able to flexibly change batches and execute instructions according to new procedures to complete product inspection. Along the way, also keep an eye out for the workers sanding the car seats, a project that also demands high levels of human-robot collaboration.

03Solution

The above requirements have not stumped collaborative robots. On the contrary, the advantages of cobots are fully realized. In the end, the customer chose to use the Elite EC66 collaborative robot, and equipped the robot with a vision system to inspect the car seat. In the project, the “easy-to-use” and “flexible” characteristics of the Elite robot are demonstrated: we side-mounted the collaborative robot into the existing car seat production line, and the almost spherical working range of the Elite robot can perfectly Covering the stations that need to be inspected, ensuring multi-angle and all-round inspection.Sourcing metal supply company Manufacturer from China

And another “safety” feature of the Elite robot also plays a role. It can work directly with humans without using safety fences for isolation. Its built-in collision detection is highly reliable and safe, providing human-robot collaboration. strong guarantee. What surprises customers even more is that Elite provides a wealth of communication interfaces, allowing customers who are accustomed to using Profinet slave communication interfaces to gain great convenience. In addition, the collaborative robot can preset programs. When the product batch is changed, the new program can be quickly called to debug the robot, and the robot can be quickly put into new tasks, helping customers to greatly shorten the line change time.

Today, the automotive industry is also developing towards “flexible” production. In fact, more and more industries are beginning to shift to a small-batch, multi-variety production model. For companies similar to the client in this case, the sooner they are ready to deal with such changes in production configuration, the sooner they will seize the opportunity for the change and the sooner they will grasp the business opportunities. Sourcing metal supply company Manufacturer from China