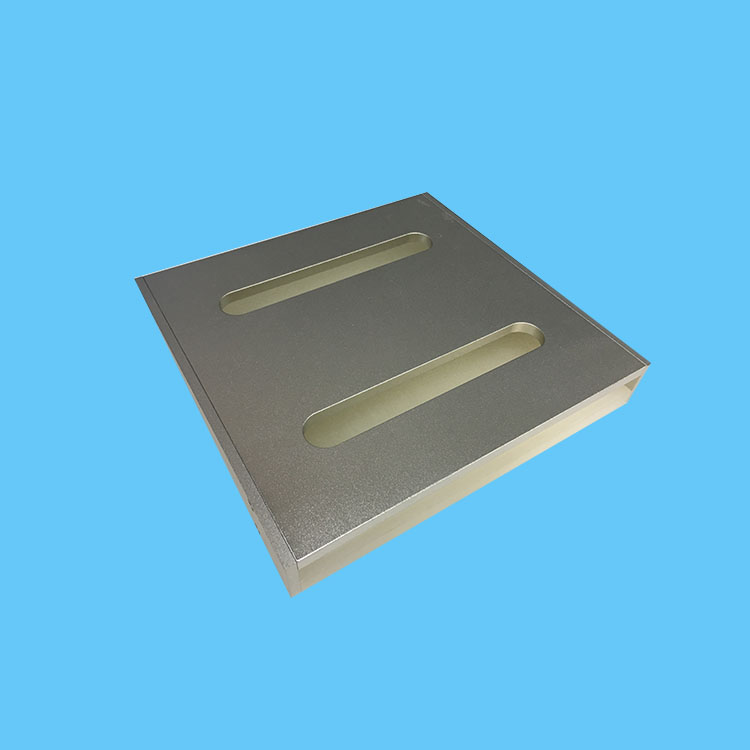

Factory Customized hardening copper from Xiamen China

The machine bed is the basic part of the machine tool, and it is required that the machine bed should have high enough static and dynamic stiffness accuracy retention. It is necessary to maintain good cold and hot processing performance of the machine bed. It is an indispensable basic equipment in the machinery manufacturing industry, and is generally used as the bed of various large-scale machine tools. Runsheng Electromechanical provides milling machine bed, planer bed, boring machine bed, grinder bed, lathe bed and other casting products for the majority of users, which are used in machine tools, machinery, automobiles, shipbuilding, electric power and other industries. Product performance and quality Has been recognized by the majority of users. Factory Customized hardening copper from Xiamen China

The production of the machine bed adopts a complete resin sand production line, all of which are resin sand and lost foam casting, with high dimensional accuracy, uniformity, no boxing, no flash or burr in the casting; the surface smoothness is close to that of precision casting, and the internal structure is stable . The entire production process of the machine bed is pollution-free and environmentally friendly, which can eliminate or reduce casting defects such as trachoma, air and air.

Types of annealing of machine bed: Common annealing processes include: recrystallization annealing, stress relief annealing, spheroidizing annealing, complete annealing, etc. Factory Customized hardening copper from Xiamen China

Features of the machine bed:

(1) Good shock absorption. Because graphite in cast iron is good for lubrication and oil storage, it is good. Also, due to the presence of graphite, gray cast iron is better at shock absorption than steel. Factory Customized hardening copper from Xiamen China

(2) The process performance is good. Due to the high carbon content of gray cast iron, which is close to the eutectic composition, the melting point is relatively low, the fluidity is good, and the shrinkage rate is small, so it is suitable for casting with complex structure or thin-walled castings. In addition, the machinability of gray cast iron is better than that of steel because graphite facilitates chip breaking during cutting. Factory Customized hardening copper from Xiamen China。