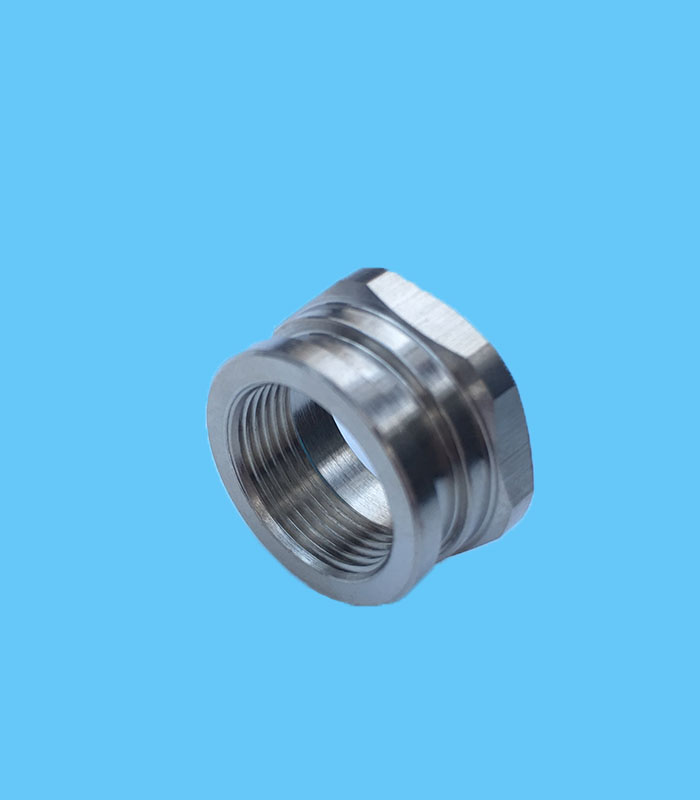

OEM CNC machining metal parts galvanized fittings

The difference between the gas shielded welding machine and other welding machines is that it is a three-in-one equipment of machinery, electricity and gas. During the use process, the problems that occur should be understood, analyzed and solved from three factors. Generally speaking, failure to weld is a circuit failure, poor welding is a mechanical failure, and poor welding is a process problem or impure shielding gas, gas circuit problems and other reasons. OEM CNC machining metal parts galvanized fittings

a mechanical problem

Whether the inlet mouth, middle mouth and outlet mouth are concentric on a straight line. If it is not in a straight line, it will easily lead to increased wire feeding resistance, resulting in unstable wire feeding;

Whether the wire feed roller slips. For the first test machine, the anti-rust grease should be wiped off and the wheel grooves should be cleaned regularly. Pay attention to wipe it off with soft things. Judge whether the wheel groove is seriously worn: in general, let the welding wire expose 1/3 of the groove surface, otherwise the wire feed wheel with the corresponding wire diameter should be replaced. The wheel groove must be installed according to the diameter of the welding wire. The retaining ring of the positive wire feeding wheel only plays the role of preventing the wheel ring from falling off or too much movement during the wire feeding process. OEM CNC machining metal parts galvanized fittings

Due to the long-term use of the wire feeding hose (wire guide tube), the wire guide tube is full of dust and iron dust, which will also cause high wire feeding resistance, so it should be cleaned frequently. When the wire guide tube has been used for a period of time, but it is still relatively new, it can be cleaned with compressed air when cleaning (the nylon tube can only be used in this way); Soak the solvent for a while, then clean up. When replacing the wire guide tube, select a suitable hose according to the diameter of the welding wire, and cut the length of the hose according to the actual length of the gun, and be sure to remove the burr at the mouth of the spiral steel wire; in addition, when welding at low speed, the filament can be used in a super gear. The wire guide tube with the diameter of the welding wire, but the thin wire wire guide tube is not allowed for the thick wire, such as: Φ1.2 wire can use the wire guide tube of Φ1.6 wire, but the wire guide tube of Φ1.6 can not use the wire guide tube of Φ1.2 . When welding at high speed, the wire feeding tube should be matched strictly according to the diameter of the welding wire;

When the hole of the contact tip is too large, it should be replaced in time, otherwise there will be problems that the welding process is unstable or the output current is not large enough due to the large gap and poor conduction. The use of anti-spatter agent in the welding process can prolong the life of the contact tip, and at the same time, the spatter in the welding torch sheath should be cleaned in time during the welding process. The contact tip of the steel wire should have a diameter of 0.1-0.2mm larger than the diameter of the wire and a length of about 20-30mm. For aluminum welding wire, it is necessary to appropriately increase the diameter of the contact tip (0.2~0.3mm larger than the diameter of the welding wire) and the length to reduce the wire feeding resistance and ensure reliable conduction. large aperture;

For the selection of the gun, it is recommended to use a standard 3m gun under the condition of satisfying the working radius. The welding torch cable must not have dead bends when in use, especially when the welding torch handle is adjacent to the cable, great attention must be paid to keep the wire feeding smooth; OEM CNC machining metal parts galvanized fittings

The selection of pressing force should be appropriate. Generally, the pressure adjustment handle can be tightened at the scale of 2 to 4, but not too tight, so as not to deform the welding wire and increase the wire feeding resistance (especially when welding aluminum and flux-cored welding), and also accelerate the wear of the wheel groove;

The support shaft of the wire feeding reel, because the shaft is made of aluminum alloy, will wear and tear with the plastic hole for a long time in the process of use, and its surface should be cleaned and greased frequently;

The direction of rotation of the wire spool should be clockwise and not counter-clockwise. OEM CNC machining metal parts galvanized fittings

Second circuit problem

Whether the aviation plug, socket, secondary cable, and ground wire are properly connected and in good contact.

(1) Correct connection method of aviation plug

When the aviation plug is inserted, the positioning slots of the plug and socket (corresponding to width and narrowness) should be correctly aligned, and then locked by turning right. At this time, the socket positioning lock just enters the plug positioning locking hole. Handle with care to avoid hard damage.

(2) The phenomenon that occurs when the aviation plug is connected virtually

A. Press the gun without any action response (solenoid valve, motor does not respond).

b. The normal display range of the power panel is voltage 15~48V, current preset digital scale 30~280, abnormal display voltage is 60~70V, current preset scale is about 400, the specific value is related to the grid voltage.

c. Current and voltage are not adjustable.

(3) Correct connection method of secondary cable

The connection method of the secondary cable quick connector is to align the inner groove of the secondary output socket on the front panel of the power supply, push it forward and rotate it about 90° to the right. OEM CNC machining metal parts galvanized fittings

(4) The phenomenon that occurs when the secondary cable and the ground wire are connected virtually

A. Serious heat at the joint, or even adhesion;

b. When welding at high current, the corresponding welding voltage exceeds the normal matching range;

c. When welding at low current, the welding process is unstable;

D. Decreased adaptability to dry elongation (shorter).

Handling of extension cords

Usually we can lengthen it to 50m/50mm2. When there are special requirements, it is recommended to increase the cross-sectional area of the cable. However, when the cable is lengthened, the error between the wave control sampling and the arc voltage will increase due to the increase of the line loss. , the given voltage should be appropriately increased.

Arc ignition problem (under the condition that the welding circuit is guaranteed to be good)

The old circuit boards are designed according to the 1.6 wire. When using other wires such as Φ1.0 and Φ1.2, the arc ignition current is always high. Now the new circuit boards have overcome this problem.

Three protective gas and gas circuit problems

Shielding gas and gas circuit problems (welds are easily oxidized, especially when welding aluminum alloys)

The purity of CO2 gas has a great influence on the compactness and plasticity of the weld metal. The purity of CO2 gas used for welding should not be lower than 98% (volume method), and its water content should be less than 0.005% (weight method). OEM CNC machining metal parts galvanized fittings

Is the shielding gas flow sufficient?

Check the gas flow V=(12~15)L/min. When welding with high current, the gas flow should be appropriately increased (selected according to the current or nozzle aperture).

Is the gas heater working?

Check that the heater is working properly. Wait 2 to 3 minutes after powering on the heater, and the heater should feel warm when you touch it with your hand. If it is not heated, it will cause frost on the heater, or even block the airflow channel or increase the probability of pores appearing.

Whether the wire guide tube is damaged or leaks.

Is the shunt broken?

If it is damaged, it should be replaced, otherwise it will affect the distribution and flow of the protective gas, resulting in poor protection.

Whether the trachea is broken.

Whether the sealing rings in the gun body are normal. OEM CNC machining metal parts galvanized fittings

CNC Machining Service & CNC Machining partsCNC Machining Experts serving Global Industries. Deliver perfect parts, on time, at affordable prices. Armed with the industry-leading technology and techniques. All samples are free!China’s largest manufacturing companies. Precise component manufacture ltd. Rapid prototype machining, rapid prototype parts.