描述

| Industries Served: | Machinery, Electronics, Automatic equipment, Hardware, Automobiles, Computers, Chemical, Medical instrument, Defense, Printing etc. |

| Equipment List: | DMG 5 axis CNC machining center / HASS composite CNC machine / CNC Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Wire-cuts / Laser Cuts / CNC Shearing Machines / CNC Bending Machines / etc. |

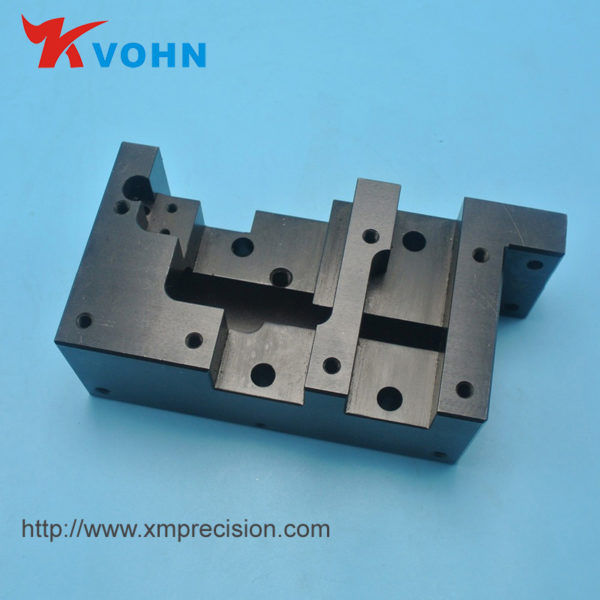

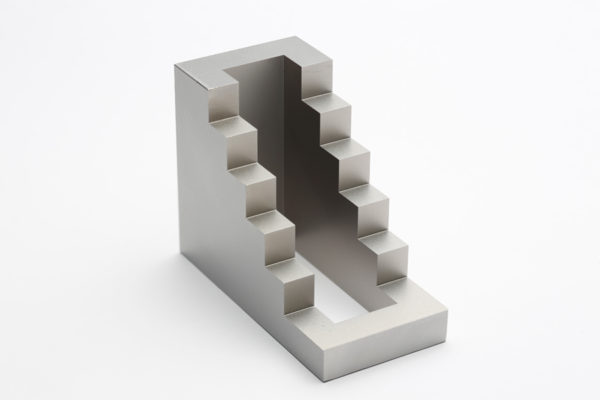

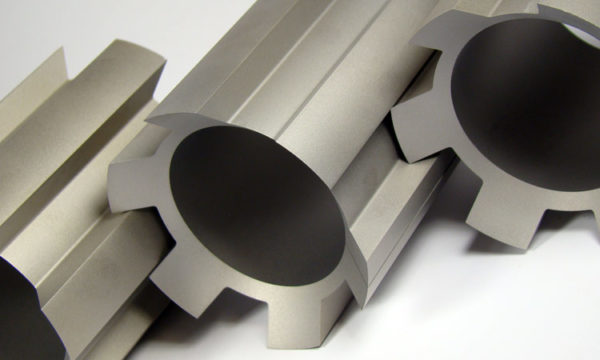

| Capabilities: | CNC Turning, CNC Milling, Wire EDM Cutting, Metal Fabrication, Grinding, Laser Cutting, Welding, Assembling, Plastic Injection Molding, Photo Chemical Milling, CNC Plasma Cutting, CNC Turret Punching, Waterjet Cutting, Secondary Processes, Laser Marking Services etc. |

| Materials Capabilities: | Aluminum Parts, Brass Parts, PTFE Parts, Copper Parts, Steel Parts, Acetal Parts, Stainless Steel Parts, Polycarbonate Parts, Polystyrene Parts, Sheet Metal Parts, Fiberglass Parts, Carbon Fiber Parts, Nylon Parts, Titanium Parts, ABS Parts, PVC Parts, Sterling Silver Parts, Spring Steel Parts, Bronze Parts, Plastic Parts, Rubber Parts, Acrylic Parts etc. |

| Custom Machined Parts: | Auto Parts, Electronics,Enclosures, Flat Washers, Front Panels, Gaskets, Golf Putters, Heatsinks, Jewelry, Knobs, Machinery, Metal Brackets, Metal Spacers, Motorcycle Parts, Pulleys PVC Parts, Robot Parts, Shaft Supports, Sheet Metal Boxes & Enclosures, Shift Knobs, Spring Spur Gears, Steel Shafts, Toy Parts, Wrenches |

| Surface Treatment: | Anodizing/Black Oxide/Electroplating/Heat Treating/Brushing/Grinding/Polishing/Painting/Powder Coating/Nickel Plating/Galvanized |

| Inspection Equipment: | Mitutotyo three-coordinate measuring machine, Mitutoyo Tool Microscope can measure up to 300mmX x 175mmY x 220mmZOuter Micrometer, Inside Micrometer (Machine), Digimatic Micrometer, Internal Micrometer, Mechanical Caliper, Vernier Caliper, Caliper (Digital), Calipe (Machine), Caliper (Dial), diameter Scale, Depth Micrometer, Digital Caliper, Altitude Gauge, Electric Balance, 2D Measurement Inspection Instruments etc. |

| Q C: | Incoming material will be checked carefully before production. Strict processing quality control. 100% inspection before shipment. |